Aluminum Trim Oxidation Prevention

Understanding Aluminum Oxidation: The Science Behind the Problem

Aluminum is renowned for its durability and resistance to corrosion, but it isn’t immune to oxidation. When exposed to oxygen and moisture, aluminum undergoes a chemical reaction that forms a thin layer of aluminum oxide. While this layer initially protects the metal from further degradation, environmental factors like salt, industrial pollutants, and acidic compounds can break it down over time. Understanding this process is critical to developing effective prevention strategies. Oxidation isn’t always visible immediately—subtle discoloration or a chalky residue often signals the start of damage.

Common Causes of Aluminum Trim Oxidation

Aluminum trim oxidation is often accelerated by environmental stressors. Coastal areas, where salt-laden air is prevalent, pose a significant risk. Road salt used in winter climates and industrial pollution containing sulfur compounds can also corrode protective coatings. Even routine exposure to acidic cleaners or hard water minerals weakens aluminum’s natural oxide layer. Poor maintenance habits, such as infrequent cleaning or ignoring early signs of wear, allow oxidation to deepen. Identifying these triggers helps homeowners and businesses tailor their prevention plans to local conditions.

Effective Cleaning Techniques to Prevent Oxidation

Regular cleaning is the first line of defense against oxidation. Use a pH-neutral cleaner and a soft microfiber cloth to avoid scratching the surface. For stubborn grime, a mixture of water and mild dish soap works well—never use abrasive pads or harsh chemicals like bleach. Rinse thoroughly with clean water to remove residue, and dry the trim completely to prevent water spots. Incorporating this routine every 4–6 weeks, especially in high-humidity or high-pollution areas, maintains the integrity of the aluminum and its protective coatings.

Protective Coatings and Sealants: Long-Term Defense

Applying a protective coating creates a barrier between aluminum and corrosive elements. Automotive-grade wax, polymer sealants, or ceramic coatings are popular choices. These products fill microscopic pores in the metal, repelling water and contaminants. For outdoor applications, UV-resistant formulas prevent sun damage that can degrade coatings over time. Reapply sealants annually or as recommended by the manufacturer. Always ensure the surface is clean and dry before application to maximize adhesion and effectiveness.

Regular Maintenance Routines for Lasting Protection

Consistency is key to preventing oxidation. Create a maintenance schedule that includes visual inspections for early signs of wear, such as dull spots or rough textures. Combine cleaning with lubrication for moving parts like window tracks or sliding doors. In winter, rinse trim frequently to remove road salt. Store outdoor furniture or decor made of aluminum in dry, covered areas during harsh weather. Documenting maintenance activities helps track patterns and adjust routines based on seasonal needs.

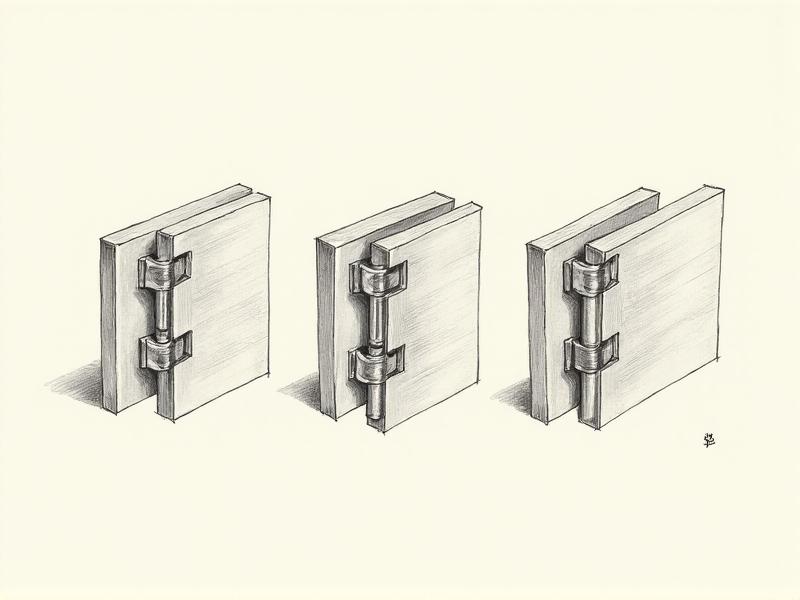

Repairing Oxidized Aluminum Trim: Steps to Restore Shine

If oxidation has already occurred, start by sanding the affected area with fine-grit sandpaper (600–800 grit) to remove the damaged layer. Follow with a metal polish to restore shine, using a circular motion and a clean cloth. For deep corrosion, consider using a chemical aluminum cleaner designed to dissolve oxidation. After restoring the surface, apply a fresh coat of sealant to prevent recurrence. Always test repair methods on a small, inconspicuous area first to avoid unintended damage.

Choosing the Right Products for Aluminum Care

Not all products are suitable for aluminum. Avoid those containing chlorine or ammonia, which can accelerate corrosion. Look for cleaners and sealants labeled specifically for metal or automotive use. Read ingredient lists for additives like PTFE (Teflon) or silicone, which enhance durability. For eco-conscious consumers, biodegradable options are available. Consulting reviews or seeking professional recommendations ensures compatibility with your trim’s finish and environmental conditions.

Environmental Factors and Mitigation Strategies

Geography plays a major role in oxidation risk. Homes near oceans should prioritize more frequent sealant applications, while urban properties might focus on pollution-resistant coatings. Installing overhangs or awnings reduces direct exposure to rain and UV rays. Landscaping choices matter too—avoid placing sprinklers near aluminum trim to minimize constant moisture. Tailoring strategies to your locale ensures resources are spent effectively.

DIY vs. Professional Services: What’s Best for Your Trim?

DIY methods are cost-effective for minor upkeep, but severe oxidation may require professional intervention. Specialists use industrial-grade tools and coatings that last longer than consumer products. They can also identify underlying issues, like improper installation that traps moisture. Evaluate the extent of damage, budget, and personal expertise before deciding. Many companies offer free inspections, making it easier to weigh options without upfront costs.

Case Studies: Successful Oxidation Prevention in Real-World Scenarios

A waterfront hotel in Florida implemented bi-annual ceramic coating applications on its balcony railings, reducing oxidation-related repairs by 70% over three years. In a Midwest industrial complex, switching to alkaline-based cleaners eliminated mineral deposits that accelerated corrosion. These examples highlight the importance of tailored solutions. Documenting such cases provides actionable insights for readers facing similar challenges.

Avoiding Common Mistakes in Aluminum Trim Care

One frequent error is using steel wool or rough brushes, which scratch the surface and invite moisture penetration. Neglecting to rinse cleaners thoroughly leaves residues that attract dirt. Over-applying sealant creates a sticky film that traps pollutants. Another pitfall is ignoring manufacturer guidelines—using a product meant for vinyl on aluminum can cause chemical reactions. Education and attention to detail prevent these missteps from undermining prevention efforts.