Belt Sizing Charts for Obsolete Models

The Importance of Maintaining Obsolete Belt-Driven Machinery

Obsolete machinery often forms the backbone of niche industries, from vintage textile mills to legacy automotive manufacturing. These machines rely on belts that have long been phased out of production, making proper sizing a critical yet challenging task. Without accurate belt dimensions, even minor repairs can lead to prolonged downtime, costly replacements, or irreversible damage to irreplaceable equipment. Preserving these systems isn’t just about nostalgia—it’s a practical necessity for businesses that depend on specialized, low-volume production.

Many industries face regulatory or logistical hurdles when upgrading to modern machinery. Retrofitting isn’t always feasible, and sourcing original parts requires navigating a labyrinth of discontinued suppliers. Belt sizing charts act as lifelines here, offering a roadmap to keep these workhorses operational. Without them, companies risk losing decades of institutional knowledge along with the machines themselves.

Challenges in Sourcing Discontinued Belt Specifications

Locating accurate belt specifications for obsolete models is akin to detective work. Original manufacturers may have closed, merged, or purged archives. Even when data exists, it’s often buried in microfiche records or handwritten logs. Digital conversions of pre-1980s machinery manuals are rare, and terminology changes—such as shifts from fractional inch to metric measurements—add confusion.

Third-party suppliers sometimes reverse-engineer belts for vintage machinery, but inconsistencies arise. A “Classic V-Belt” from one vendor might differ slightly in taper angle or tensile cord placement from another’s, leading to premature wear. This underscores the need for precise, machine-specific charts rather than generic replacements.

Reverse-Engineering Belt Dimensions: A Practical Guide

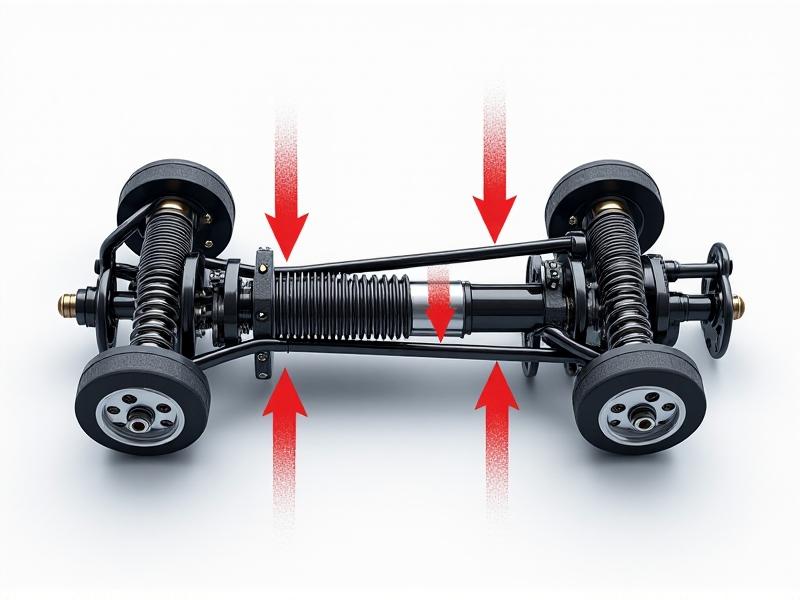

When documentation is lost, creating a custom sizing chart becomes essential. Start by measuring the existing belt’s pitch length—the distance between two pulley centers—using non-stretch string. For width and thickness, digital calipers provide micron-level accuracy. Note cross-sectional shapes: not all “V-belts” have the same angle, and variations impact grip and torque capacity.

Document groove profiles on pulleys with brass rubbing paper or 3D scanning apps. These details help match belts to pulley geometry, preventing slippage. For multi-belt drives, ensure matched sets to distribute load evenly—mixing worn and new belts stresses components.

Case Study: Reviving a 1960s Agricultural Conveyor System

Midwest Grain Co. faced a critical breakdown when their legacy conveyor’s main drive belt snapped. Original specs were lost in a 1987 warehouse fire. Technicians measured remnants and pulley grooves, discovering the belt used an uncommon 34-degree angle. Cross-referencing with European military surplus records revealed a match, allowing custom production.

This project highlighted the value of collaboration: retired engineers provided insights into period-specific materials, avoiding modern synthetic compounds that would have degraded faster in dusty conditions.

Building a Future-Proof Belt Archive: Best Practices

Digitize existing charts with OCR scanners, embedding metadata like machine model numbers and environmental factors (e.g., “high-humidity use”). 3D laser scans of pulleys create reference files for CNC replication. Partner with local makerspaces to crowdsource dimensions for rare machinery—many hobbyists maintain niche archives.

Use cloud storage with redundancy: Google Drive for accessibility, paired with archival-grade M-Discs for physical backups. Encourage suppliers to add vintage specs to their databases by offering anonymized measurement data—this builds a community resource.

Where to Find Help: Networks for Obsolete Machinery Support

Online forums like VintageMachinery.org host user-contributed manuals and CAD files. Industrial museums often permit access to their reference libraries for research fees. Universities with mechanical engineering programs may assist through student projects, combining education with real-world problem-solving.

Lastly, don’t underestimate local machine shops. Many retain tooling for obsolete belt profiles and can craft small batches if provided with precise dimensions. Building these relationships ensures ongoing support for heritage equipment.