Power Supply Filtering Upgrades

Understanding Power Supply Noise and Its Impact

Power supplies are the backbone of electronic systems, but their performance is often compromised by electrical noise. This noise—ripple, harmonics, or electromagnetic interference (EMI)—originates from switching components, load variations, or external sources. Left unchecked, it can distort signals, reduce efficiency, and shorten component lifespan. For example, in audio equipment, power supply noise manifests as hum or hiss, while in digital systems, it introduces data errors or instability. Filtering upgrades aim to suppress these disturbances by isolating sensitive circuits from noisy power rails.

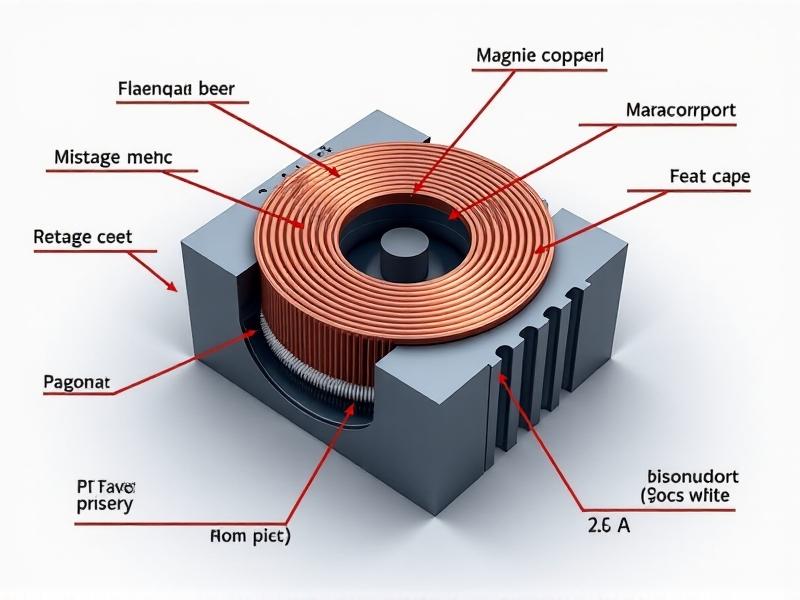

Key Components in Power Supply Filtering

Effective filtering relies on strategic component selection. Capacitors act as local energy reservoirs, smoothing voltage spikes. Electrolytic capacitors handle low-frequency ripple, while ceramic or film types target high-frequency noise. Inductors, such as chokes or ferrite beads, block alternating currents by introducing impedance. Resistors and damping networks dissipate unwanted energy, and voltage regulators maintain stable output. For instance, combining a bulk capacitor (100–1000µF) with a parallel ceramic capacitor (0.1µF) addresses both low- and high-frequency noise. These components form LC (inductor-capacitor) or RC (resistor-capacitor) filters tailored to specific noise profiles.

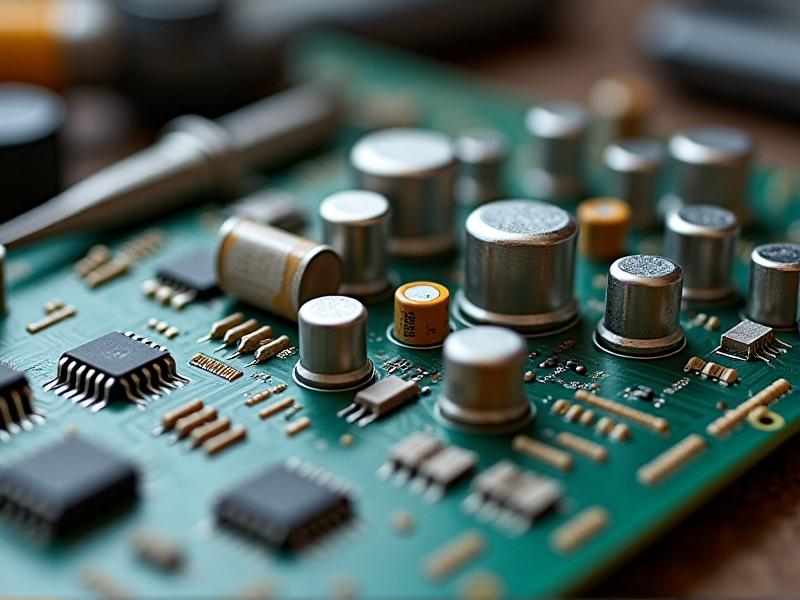

Common Upgrade Techniques for Enhanced Filtering

Upgrading power supply filtering often starts with adding bypass capacitors near noise-sensitive ICs. For example, placing a 0.1µF ceramic capacitor across a microcontroller’s power pins shunts high-frequency noise to ground. Installing larger energy storage capacitors (e.g., 2200µF) at the supply input reduces voltage sag during load spikes. Ferrite beads on power cables suppress EMI, while linear regulators replace noisy switching counterparts. Advanced users might implement π-filters (capacitor-inductor-capacitor) or active filtering circuits using op-amps. Proper grounding—star grounding or separating analog/digital grounds—also minimizes noise coupling.

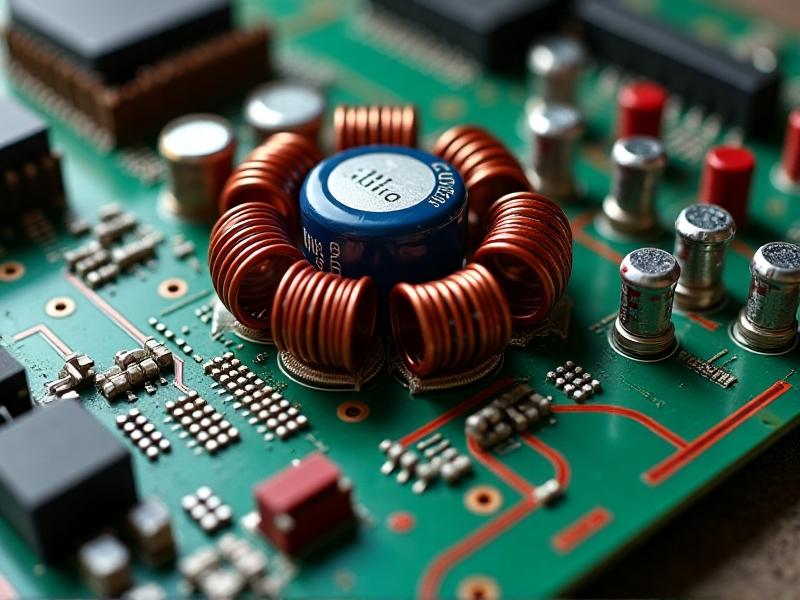

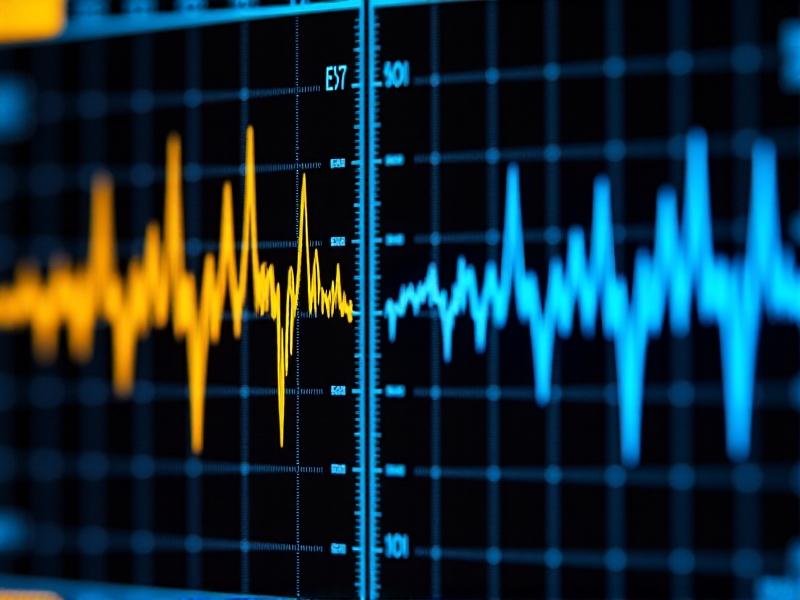

Practical Applications in Audio and High-Fidelity Systems

In audiophile setups, power supply noise directly impacts sound quality. Upgrading an amplifier’s filtering stage might involve replacing stock capacitors with low-ESR (Equivalent Series Resistance) types or adding snubber circuits to suppress transformer ringing. Linear power supplies with toroidal transformers and LC filters are preferred over switching supplies for their cleaner output. For example, a DIY audio enthusiast could install a choke-input filter to reduce rectifier-induced ripple. Measurements using spectrum analyzers often reveal reduced harmonic distortion post-upgrade, translating to clearer audio reproduction.

Advanced Methods: EMI Shielding and Multi-Stage Filtering

For industrial or medical devices, multi-stage filtering and shielding become critical. Shielded enclosures with conductive gaskets block external EMI, while common-mode chokes neutralize interference from power cables. Multi-layer PCBs with dedicated power planes reduce impedance, and feedthrough capacitors filter noise at enclosure entry points. In one case study, a robotics controller’s reliability improved by 40% after adding an RC snubber network to its motor driver and shielding the DC-DC converter. Simulations using SPICE or ANSYS SIwave help optimize filter designs before prototyping.

DIY Guide: Upgrading Consumer Electronics

Enthusiasts can upgrade household devices like gaming PCs or routers by retrofitting filter components. For a PC’s GPU, adding low-ESR polymer capacitors near the VRM (Voltage Regulator Module) reduces voltage ripple, enhancing overclocking stability. A Raspberry Pi might benefit from a π-filter on its 5V input to minimize SD card errors. Essential tools include a soldering iron, desoldering braid, and multimeter. Safety precautions—discharging capacitors and avoiding live circuits—are paramount. Online communities often share oscilloscope measurements pre- and post-modification to validate improvements.

Future Trends in Power Supply Filtering

Emerging technologies like GaN (Gallium Nitride) transistors and active noise cancellation are reshaping filtering. GaN’s faster switching reduces parasitic losses, enabling compact, efficient filters. Active techniques inject anti-phase noise to cancel disturbances in real-time, as seen in premium automotive infotainment systems. Researchers are also exploring AI-driven adaptive filters that adjust parameters based on load conditions. As renewable energy systems and EVs proliferate, robust filtering will remain pivotal in managing complex power networks.