Strobe Light Accuracy Verification

The Fundamentals of Strobe Light Accuracy

Strobe lights are integral to industries ranging from aviation to entertainment, where timing and precision are non-negotiable. Ensuring their accuracy involves verifying flash duration, intensity, and synchronization against defined standards. Even minor deviations can lead to safety risks or operational inefficiencies. For instance, in aviation, misaligned strobe timing might compromise runway visibility, while in photography, inconsistent flashes could ruin critical shots.

Why Strobe Light Verification Matters

Accuracy in strobe lights isn’t just technical—it’s a matter of compliance and safety. Regulatory bodies like the FAA and ISO enforce strict guidelines for strobe performance. For example, runway lights must pulse within 1-2% of the specified frequency to avoid pilot disorientation. Similarly, concert venues rely on synchronized strobes to create seamless visual effects without overwhelming audiences. Verification ensures reliability, minimizes liability, and prevents costly rework.

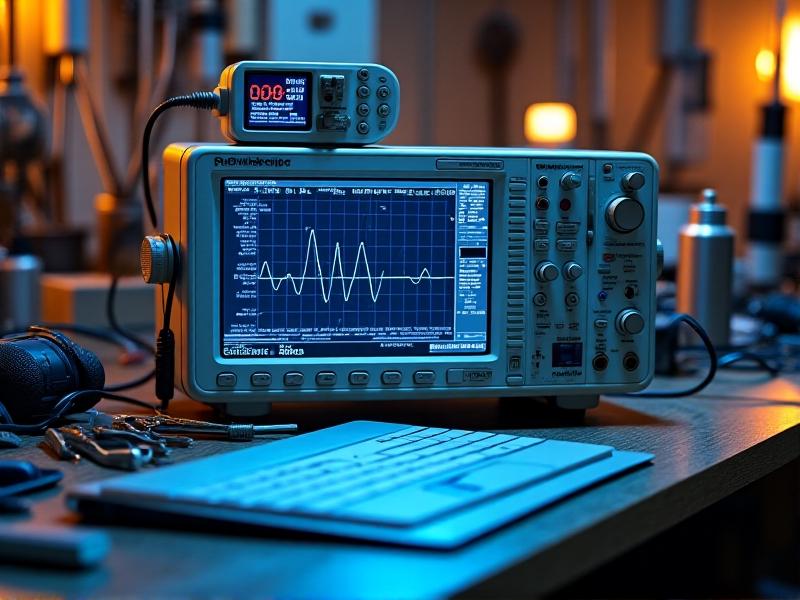

Tools and Techniques for Verification

Modern verification relies on photometric sensors, oscilloscopes, and specialized software. Photometers measure light intensity, while high-speed cameras capture flash duration down to microsecond resolutions. Tools like spectral analyzers assess color consistency, critical for applications like film production. Calibration often follows a three-step process: baseline testing, adjustment via pulse-width modulation, and final validation against international standards.

Navigating Industry Standards and Protocols

Standards such as ICAO Annex 14 and IEC 60598-2-23 dictate strobe light requirements across sectors. These protocols define parameters like flash energy, rise time, and chromaticity. Compliance often requires third-party certification, involving rigorous environmental testing (e.g., temperature extremes, vibration). Understanding these frameworks helps organizations tailor verification processes and avoid non-conformance penalties.

Real-World Case Studies in Verification

A 2022 case at a European airport revealed that aging strobes caused irregular flashes, detected during routine verification. Post-calibration, the system achieved 99.8% sync accuracy. In another example, a film studio avoided reshoots by catching a strobe’s color shift during pre-production testing. These cases underscore the value of proactive verification in averting operational disruptions.

Future Trends in Strobe Light Technology

Advances in IoT-enabled strobes allow real-time remote monitoring, reducing manual verification. Machine learning algorithms now predict degradation patterns, enabling preemptive maintenance. Meanwhile, adaptive strobes that self-adjust based on ambient conditions are emerging, promising greater energy efficiency and accuracy. These innovations will redefine how industries approach verification in the next decade.