Tape Speed Calibration Tools

Understanding Tape Speed and Its Critical Role in Audio Fidelity

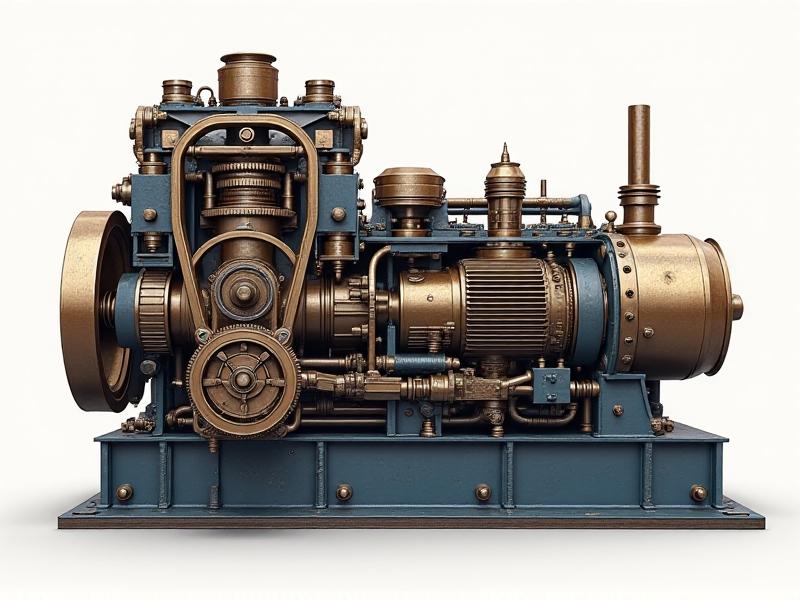

Tape speed calibration is the unsung hero of analog audio preservation and reproduction. Whether working with vintage reel-to-reel decks or cassette players, the accuracy of tape speed directly impacts pitch consistency, tonal balance, and temporal alignment. A misaligned transport mechanism can turn a vibrant recording into a warbled, out-of-tune relic. Historically, engineers relied on meticulous calibration to ensure that a 15 IPS (inches per second) reel-to-reel tape didn’t play back at 14.9 IPS—a subtle difference that could skew musical harmonies or dialogue clarity in film archives. This section explores why even minor deviations matter and how they affect both artistic intent and technical integrity.

Essential Tools for Precise Tape Speed Calibration

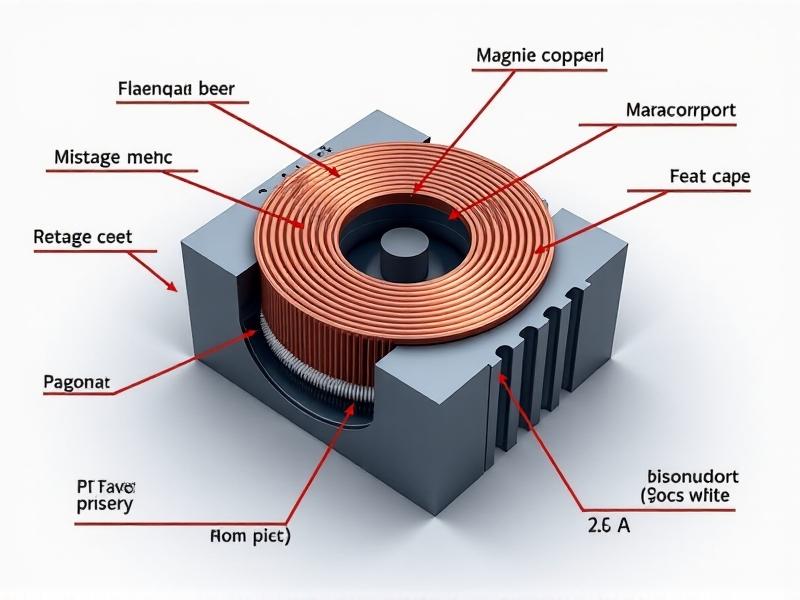

Calibrating tape speed demands specialized tools designed to measure and adjust mechanical systems with microscopic accuracy. Strobe discs, engraved with precise patterns, remain a staple for visualizing rotational consistency when paired with a neon or LED light source. Digital tachometers have largely replaced their analog predecessors, offering real-time RPM readouts via laser sensors. Meanwhile, reference calibration tapes—recorded with exact frequency tones—allow technicians to compare playback results against known standards. For DIY enthusiasts, smartphone apps now simulate test tones, though professional-grade hardware like the MRL reference tape or Dr. Feickert Adjust+ system still dominates high-stakes environments. This section breaks down the function, limitations, and ideal use cases for each tool.

Analog vs. Digital Calibration Tools: Pros and Cons

The debate between analog purists and digital innovators shapes modern tape calibration practices. Analog tools, such as weighted strobe discs and hand-adjusted capstan screws, offer a tactile, circuit-free approach beloved by vintage audio restorers. However, they require practiced skill to interpret strobe patterns under fluctuating light conditions. Digital tools, like USB-connected oscilloscopes or software-based analyzers, automate frequency comparisons and graph deviations over time. While these reduce human error, they depend on stable power sources and software compatibility—potential pitfalls in fieldwork. Hybrid solutions, such as the Tentaco TTS-500, merge analog durability with digital precision, illustrating how the industry balances tradition with progress.

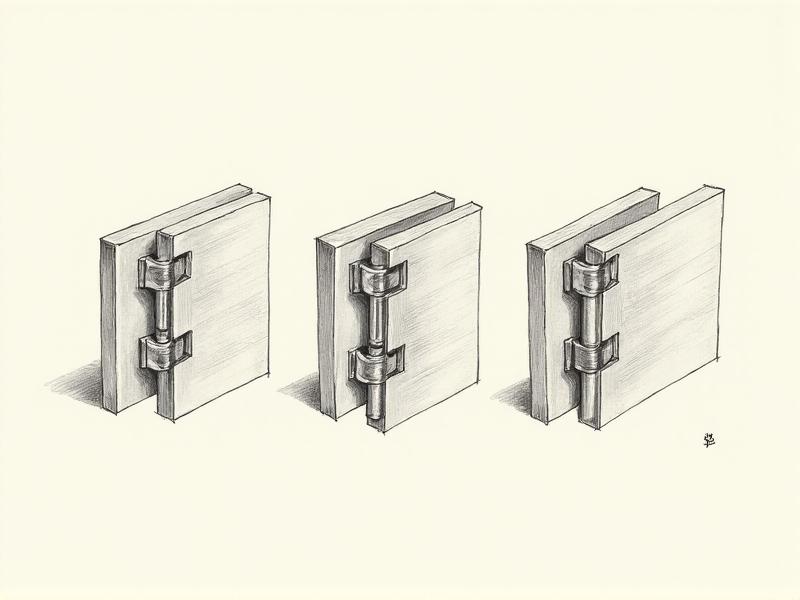

Step-by-Step Guide to Calibrating Tape Speed

Calibration begins with diagnostics. Start by playing a 3 kHz reference tape and measuring output frequency with a counter. If the result deviates, access the transport’s speed adjustment potentiometer or capstan belt. For reel-to-reel systems, strobe discs help verify capstan rotation against marked grids. Adjust the motor’s trimmer until the pattern stabilizes under strobe light. Cassette decks often require azimuth alignment first, as misaligned heads can mimic speed issues. Document each adjustment incrementally; even a 0.1% correction can realign a 30-minute tape’s runtime by seconds. This walkthrough emphasizes methodical testing, leveraging both auditory and visual feedback to achieve sub-0.5% deviation—the gold standard for professional archives.

Common Pitfalls and How to Avoid Them

Even seasoned technicians encounter calibration roadblocks. Aging capstan belts may slip unnoticed, causing irregular wow-and-flutter. Environmental factors like temperature shifts can contract metal components, altering tape tension. Over-tightening adjustment screws might solve speed inconsistencies but damage fragile transport mechanics. Another oversight? Neglecting to demagnetize heads before calibration—residual magnetism can distort reference tones. This section troubleshoots these issues, advocating for preventive maintenance logs and climate-controlled workspaces. Pro tip: Use a feeler gauge to check pinch roller pressure, and always let machines warm up to operating temperature before testing.

Real-World Applications: Case Studies from Studios and Archives

In 2019, the BBC’s archival team faced a dilemma: 1,000+ quarter-inch tapes from the 1960s played back sluggishly, skewing voice recordings of historical speeches. Using MRL reference tapes and a customized strobe system, engineers restored speeds to within 0.3% accuracy—preserving vocal cadences crucial for documentaries. Similarly, Nashville’s Analog Revival Studio recalibrates its Studer A820 machines monthly to maintain album masters for vinyl pressing. These examples underscore calibration’s role in cultural preservation and commercial audio production, where even minor errors carry financial and artistic consequences.

The Future of Tape Speed Calibration: Emerging Technologies

As analog audio enjoys a renaissance, calibration tools evolve. AI-driven software like SpeedTrackAI analyzes tape transfers in real time, applying corrective algorithms without physical adjustments. Modular hardware, such as Raspberry Pi-based tachometers, democratizes access for home archivists. Meanwhile, companies like Endless Analog develop “smart” capstan motors with self-calibrating firmware. Yet challenges persist: counterfeit reference tapes flood online markets, and 3D-printed transport parts lack OEM durability. This closing section speculates on a hybrid future where machine learning aids—but doesn’t replace—the nuanced craftsmanship of manual calibration.