Terminal Cup Corrosion Solutions

Understanding Terminal Cup Corrosion

Terminal cup corrosion is a persistent issue affecting battery performance across industries. This type of corrosion occurs at the junction where battery terminals connect to external circuits, often leading to power loss, overheating, and system failure. The process begins when acidic electrolytes or environmental moisture react with the metal terminals, forming conductive salts that eat away at the material. Over time, this degradation disrupts electrical flow and compromises safety. In automotive, industrial, and renewable energy systems, unchecked corrosion can result in costly downtime and replacements. Recognizing the early signs—such as discoloration, crusty deposits, or resistance fluctuations—is critical to addressing the problem before catastrophic failure occurs.

Causes and Contributing Factors

Several factors accelerate terminal cup corrosion. Electrolyte leakage from battery vents is a primary culprit, as sulfuric acid reacts with lead or copper terminals. Galvanic corrosion arises when dissimilar metals, like lead and aluminum, come into contact in humid environments. Environmental conditions such as coastal salinity, industrial pollutants, or temperature extremes exacerbate chemical reactions. Poor maintenance practices, like infrequent cleaning or loose connections that trap moisture, also play a role. For example, in marine batteries, saltwater spray creates a highly conductive medium that speeds up oxidation. Understanding these triggers helps tailor prevention strategies to specific use cases.

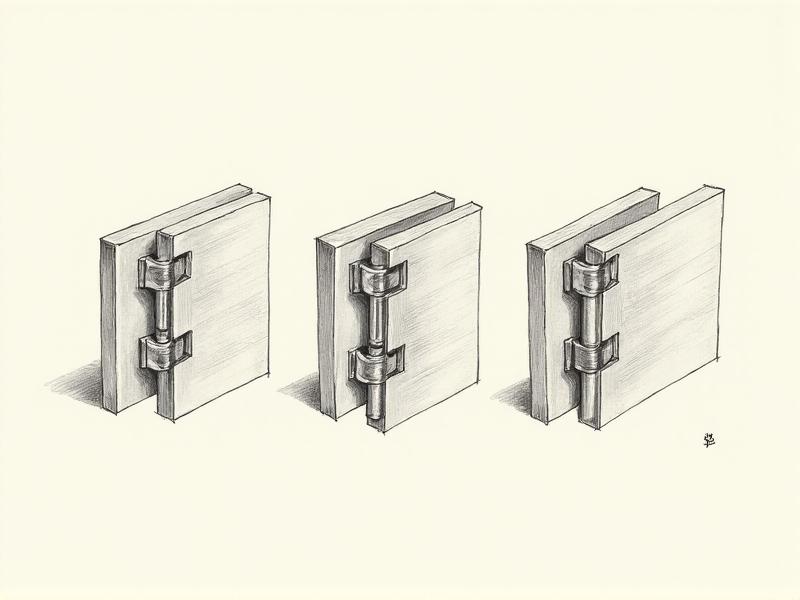

Material Selection and Engineering Solutions

Choosing corrosion-resistant materials is the first line of defense. Brass terminals with nickel or silver plating offer superior resistance compared to bare lead. Stainless steel, though costlier, is ideal for harsh environments like offshore wind turbines. Recent advancements include polymer-coated terminals that isolate metal from moisture. For instance, Tesla’s Powerwall batteries use epoxy-sealed terminals to prevent electrolyte creep. Manufacturers are also adopting bimetal designs—such as copper cores with lead exteriors—to balance conductivity and durability. These engineered solutions reduce long-term degradation while maintaining efficient energy transfer.

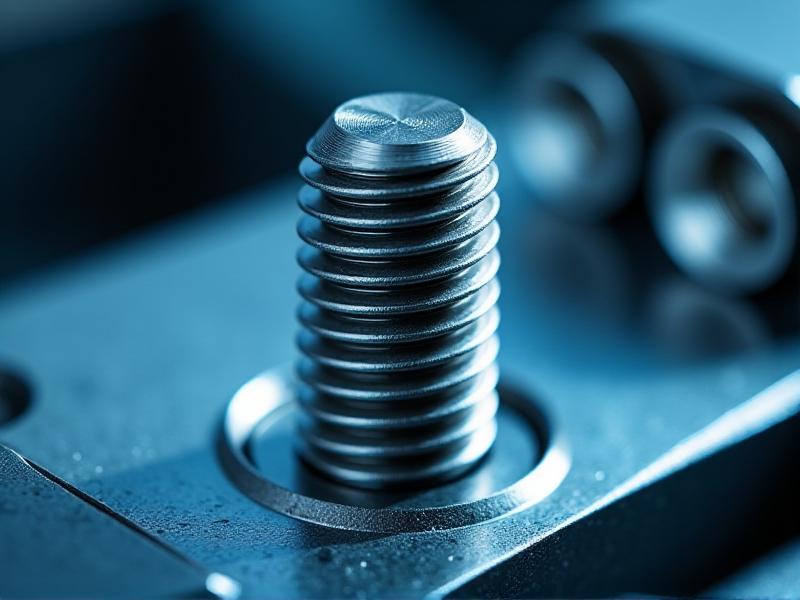

Maintenance Best Practices for Longevity

Proactive maintenance significantly extends terminal life. A mixture of baking soda and water neutralizes acidic buildup during routine cleaning. After scrubbing with a wire brush, applying a dielectric grease layer creates a moisture-resistant barrier. In telecom infrastructure, technicians use ultrasonic testing to detect sub-surface corrosion before visible signs appear. Companies like Caterpillar recommend torque-checking connections biannually to prevent gaps that trap contaminants. Implementing these practices in fleet management has reduced truck battery failures by up to 40%, according to a 2023 Transportation Energy Institute report.

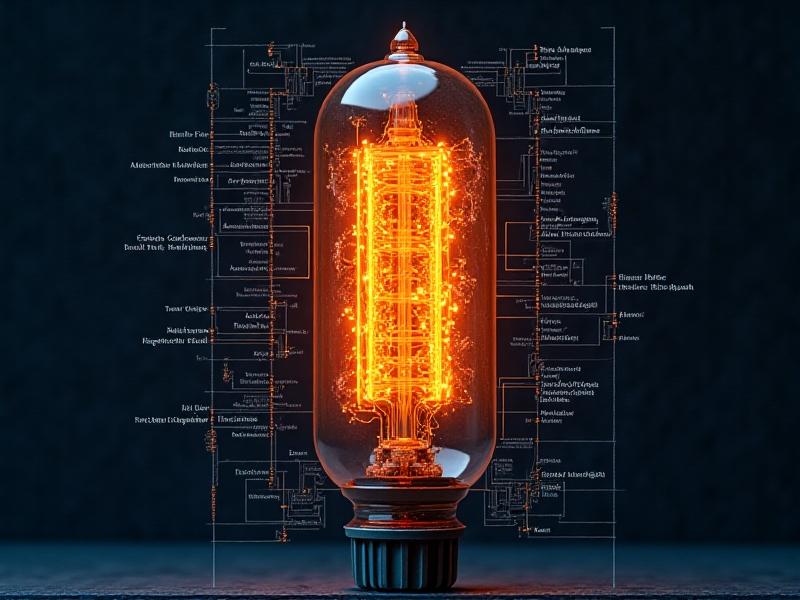

Innovations in Corrosion Resistance Technology

Cutting-edge materials like graphene-based coatings and self-healing polymers are revolutionizing corrosion control. Researchers at MIT have developed a nano-coating that repairs microscopic cracks when exposed to UV light. Meanwhile, IoT-enabled sensors embedded in terminals monitor real-time resistance changes, alerting users via smartphone apps. BMW’s latest EVs feature terminals with sacrificial zinc anodes that divert corrosive activity away from critical components. These innovations not only prolong battery life but also enable predictive maintenance models across industries.

Industry-Specific Applications and Case Studies

In solar farms, UV-resistant terminal caps paired with galvanized steel mounts have slashed replacement rates by 60%. Maritime applications benefit from silicone-sealed terminals rated for IP68 waterproofing, as seen in Volvo Penta’s marine batteries. Telecom giant Ericsson reported a 35% cost reduction after switching to aluminum-zinc alloy terminals in 5G backup systems. Each sector’s unique demands drive tailored solutions—from vibration-proof aerospace terminals to food-grade stainless steel connectors in beverage manufacturing.

Cost-Benefit Analysis of Prevention Strategies

While polymer-coated terminals cost 20% more upfront, they reduce replacement frequency by 3–5 years, yielding a 200% ROI over a decade. Conversely, neglecting maintenance in data centers can lead to $15k/hour downtime costs during outages. A 2024 DOE study found that predictive monitoring systems pay for themselves within 18 months by preventing unplanned shutdowns. Balancing initial investment against operational savings is key—for small fleets, simple grease applications offer the best bang for the buck.

Future Trends in Corrosion Mitigation

Emerging bio-inspired solutions include coatings mimicking lotus leaves’ water-repellent properties. AI-driven corrosion prediction models, trained on decades of field data, will soon forecast failures months in advance. Airbus is experimenting with terminals made from conductive ceramics that resist 1,500°C temperatures. As solid-state batteries gain traction, their non-liquid electrolytes could eliminate terminal corrosion altogether—a potential game-changer by 2030.