Transformer Oil Dielectric Testing

Understanding the Role of Dielectric Testing in Transformer Health

Transformer oil is the lifeblood of electrical transformers, serving as both an insulator and a coolant. Dielectric testing is a critical diagnostic tool to assess the oil’s ability to withstand electrical stress without breaking down. Over time, contaminants like moisture, particles, or chemical byproducts can degrade the oil’s dielectric strength, increasing the risk of catastrophic failures. Regular testing ensures operational reliability and prevents costly downtime. By analyzing the oil’s insulation properties, technicians can detect early signs of degradation and take corrective action before a transformer fails.

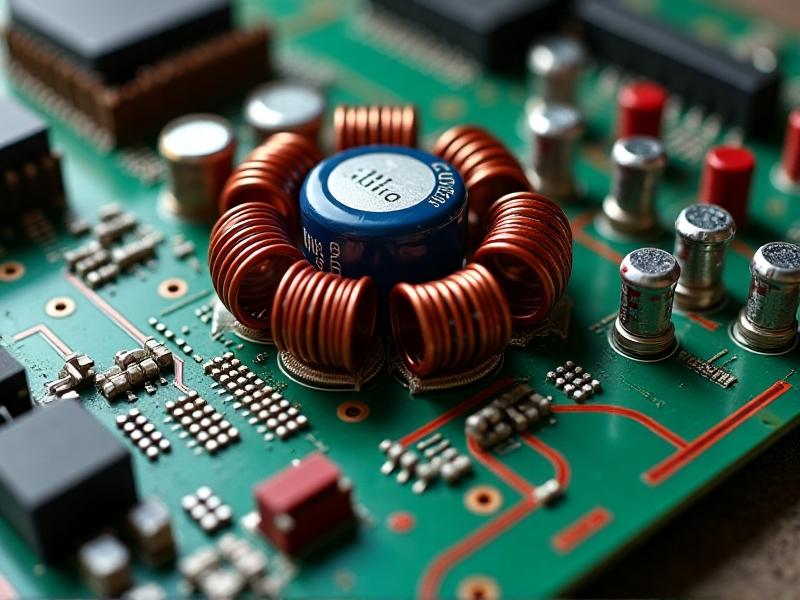

How Dielectric Testing Works: Principles and Methods

Dielectric testing measures the maximum voltage that transformer oil can endure before electrical breakdown occurs. The most common method is the breakdown voltage test, where two electrodes submerged in oil are subjected to an increasing AC voltage until an arc forms. Standards like ASTM D877 and IEC 60156 define the procedure. Advanced techniques also evaluate dielectric dissipation factor (DDF) to assess energy loss, indicating contamination or aging. These tests reveal hidden issues, such as dissolved gases or particulate accumulation, which weaken insulation performance.

Key Factors Affecting Dielectric Strength

Moisture is the primary enemy of transformer oil, as even trace amounts reduce dielectric capacity by up to 50%. Particulate matter—like cellulose fibers from aging insulation—creates conductive paths, while oxidation byproducts form sludge. Temperature fluctuations exacerbate these issues, as warming oil absorbs moisture more readily. Chemical stability is equally crucial; acids generated by oxidation accelerate degradation. Testing labs often pair dielectric assessments with moisture content analysis and acid number measurements for a comprehensive health assessment.

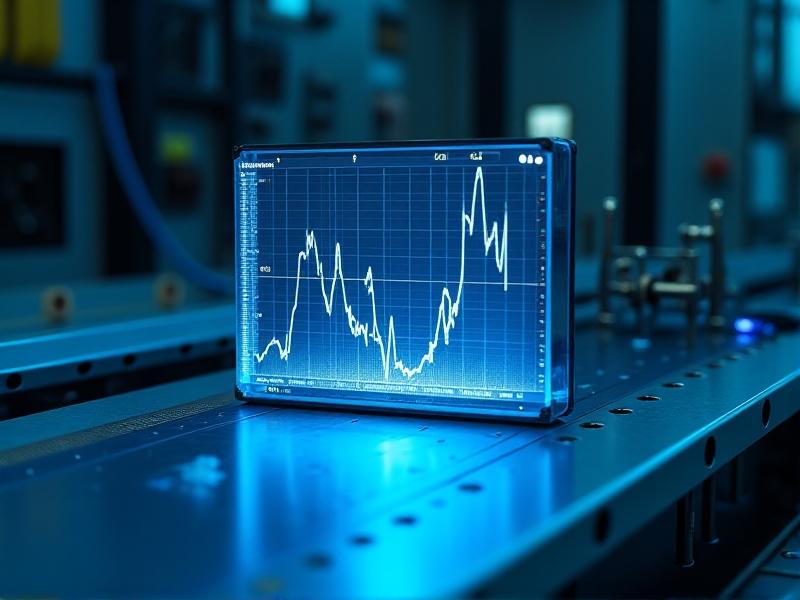

Interpreting Test Results: When to Take Action

Breakdown voltages below 30 kV typically signal immediate remediation. For DDF, values exceeding 0.5% indicate excessive polar contaminants. Trends matter: a gradual decline in dielectric strength suggests aging, while a sudden drop may point to acute contamination. Dissolved gas analysis (DGA) complements these tests; hydrogen or methane spikes hint at partial discharges eroding insulation. Proactive maintenance—such as oil filtration, dehydration, or replacement—restores performance and extends transformer lifespan.

Case Studies: Dielectric Testing in Real-World Scenarios

A 2018 study in a coastal substation found salt contamination reducing dielectric strength by 40% within six months. Another case involved a manufacturing plant where overheating caused oil carbonization, detected via elevated DDF. After vacuum dehydration and filtration, breakdown voltage rebounded to 56 kV. These examples underscore how routine testing prevents failures in diverse environments—from humid climates to industrial settings with heavy electrical loads.

Best Practices for Maintaining Optimal Dielectric Performance

Annual testing is a baseline; high-risk environments may require quarterly checks. Use sealed sampling containers to prevent moisture ingress during collection. Pair dielectric tests with furanic compound analysis to gauge paper insulation degradation. Onsite testing kits offer rapid insights, while lab-grade instruments provide precision. Training technicians to recognize early warning signs—like discolored oil or unusual gas levels—ensures timely interventions.

The Future of Dielectric Testing: Innovations and Trends

Automated sensors now enable real-time dielectric monitoring, transmitting data to centralized systems. Machine learning algorithms analyze historical trends to predict failure windows. Eco-friendly ester-based oils, with higher inherent dielectric strength, are gaining traction. These advancements promise a shift from reactive to predictive maintenance, slashing costs and enhancing grid resilience. As renewable energy systems expand, robust dielectric testing will remain indispensable for integrating transformers into smart grids.